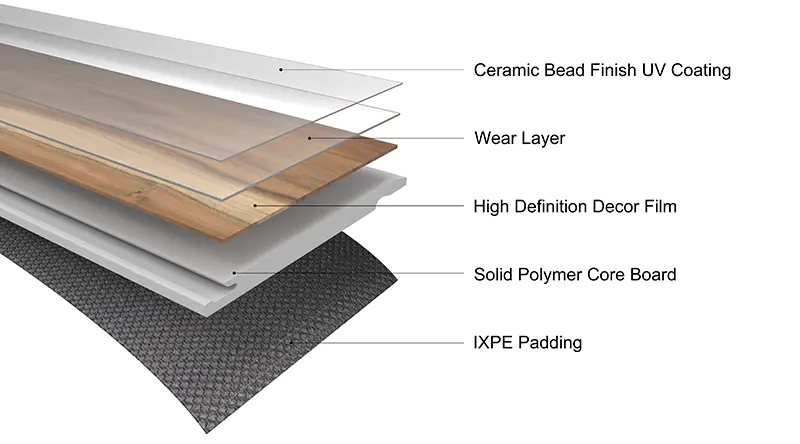

Description of the structural layers of SPC flooring

After a customer has decided to use SPC flooring for their new home, it can be a headache to choose the right SPC flooring from the many specifications available. For example there are different thicknesses, assemblage systems, and warranty specifications for each product.

When you read the following article it may help.

Of course we can’t advise you on your decorating style, what we want to do is to make you more knowledgeable about SPC flooring, not just in looks. This can help you choose and save you money.

First of all we can easily see from the side that SPC flooring consists of a multi-layer structure, which is similar to laminate flooring. It is because these layers work with each other that SPC flooring has many excellent characteristics.

UV layer

This is a layer on the surface of the flooring, the thickness of which is measured in microns. It is cured on the surface of the flooring by UV light. It is also the thinnest layer, but this layer is essential.

The UV layer can have a glossy or matt finish. It protects the surface from stains, resists UV rays and ensures that the floor does not fade after a long period of sunlight exposure.

Wear layer

The wear layer is the part between the UV layer and the decorative layer.The quality and thickness of the wear layer is your indicator for how well your floors will last over time.Wear layers are measured in mil’s (1 mil = 1 thousandth of an inch).The thickness of the wear layer is usually proportional to the manufacturer’s warranty, the thicker the layer, the longer the warranty period.

The thickness of the wear layer needs to be matched to the thickness of the core layer, generally a thin core layer is not suitable for a thicker wear layer. Because of the different materials used in the wear layer and the core layer, an overly thick wear layer increases the probability of SPC flooring Cupping.

Generally 4 mil wear layer SPC flooring, installed in the bedroom can be used for 10 years normally, if the room with higher traffic, you can choose a floor with a 10 mil wear layer, please be assured that this specification can be used with confidence for more than 20 years. If installing in a commercial you will need to choose a Flooring with 30 mil or more, under normal use these floors will be difficult to destroy, but you have to be careful with heat and exposure to the sun. It is possible that temperature will destroy them more than foot traffic.

Finish layer

The finish layer is usually 4 mil thick or less and is produced by specialized high-definition colour printing equipment. The high-quality finish layer gives the floor a realistic wood or stone grain effect, with a more designed look in terms of colour, pattern and texture.

Although this does not affect the use of the flooring, it is important that you check the flooring samples carefully. Believe me, a small sample of SPC flooring can tell the truth.

Core layer

The thickest and hardest layer of the entire SPC flooring. It is the core of the whole floor, made of stone powder and PVC resin powder fused and pressed together to make it completely waterproof. The thickness of the core layer determines the weight of the floor, as well as the thickness of the tongue and groove. The thickness of the core layer determines the weight of the floor and the thickness of the tongue and groove – a sign that more costs will be incurred.

Core thickness also serves as a noise reduction barrier and is an indicator of quality.

Core thicknesses range from 3.5mm to 7mm, with some manufacturers offering 8mm cores, the heavier the core the more pressure it puts on the floor and the less safe it is in some older homes. 4mm or so SPC flooring is very cost effective and is ideal for installation in your home.

Underlayment

SPC floor coverings are made of EVA or IXPE and are generally pre-assembled from the manufacturer with thicknesses of 1.0mm – 1.5mm.

These backings are used for sound reduction, heat retention and overall comfort.With thicker underlayment’s comes more sound reduction, With thicker underlayment’s comes more sound reduction, and impact absorption (overall comfort).

SPC flooring without underlayment can be used if your base floor has a cork layer or if you are laying over an existing wooden floor.

The use of padding can be a good improvement in noise, and if you are using it upstairs, this can be improved by adding padding or using additional padding.

summary

- It is not the most expensive SPC flooring that is the most suitable, with a balance of price and function.

- In terms of cost, the thicker the flooring the higher the price, but that doesn’t mean that thicker flooring is better.

- Choose to buy flooring based on the specific use case, not on price.

- The thicker the wear-resistant layer, the more wear-resistant it is, but will you really use the floor until it is damaged and then replace it?